|

Slab-on-grade or floating slab foundations are a structural engineering practice where the concrete slab, that is to serve as the foundation for the structure, is formed from a mold set into the ground. The concrete is then placed into the mold, leaving no space between the ground and the structure. There is no basement and no crawl space. Cracks in concrete floors often indicate slab settlement problems. This issue is most commonly found in “slab-on-grade” homes and buildings. It's when the floor slab is closer to the surface of the ground and therefore more affected by changes in the soil beneath. When changes occur in the moisture content, and density of the soils beneath a concrete slab, the result is usually slab cracking and settlement. The most common causes of slab cracking and settlement are:

These causes, among others, will eventually create a void beneath the concrete slab. If the slab isn't strong enough to span the void, it will eventually settle and break. The result is a cracked, sunken concrete slab. And once this occurs, you will most likely start to notice other signs of foundation damage throughout your home or building such as jammed doors or cracks in the walls and ceilings. Rather than breaking the inside slab of an established home, there are solutions to this issue. Polyurethane foam for lifting settled slabs is a very successful repair for slab on grade settlement. Don't let the word "foam" fool you. Structural grade polyurethane foam is engineered for heavy lifting such as this. Settled slabs are lifted, soil beneath the home is stabilized, cracks in drywall close, doors are opening and closing well again, etc. This process of concrete leveling and stabilization can be completed in a matter of a few days.

Let us be your cost effective alternative to replacement. Call today for more information Concrete Corrections 770-558-5862

11 Comments

Summer turning into fall means kids going back to school, family schedules becoming more hectic, and family budgets preparing for increased energy bills. One other thing ushered in by fall is the increasing need to complete home maintenance tasks to avoid costly repairs. A little bit of time and money spent during fall saves families a ton of time and money later when necessary systems fail because they were not maintained properly. We share the best ways for you to approach end-of-summer home maintenance to avoid costly repairs below. 1. Prevent Frozen Pipes As the weather turns cooler, families that do not take steps to prevent frozen pipes are at risk of losing hot water and experiencing water damage. Be proactive and prevent expensive damage and potential flooding by keeping your basement at least 55 degrees Fahrenheit during cold snaps. It’s also important to keep unused portions of your home at that temperature, at least, to prevent frozen pipes. During a cold snap, keep your interior doors and cabinet doors open so heat from the house can circulate and keep the pipes warm. If you think a pipe will freeze, allow the faucet to drip to prevent pressure from building and bursting it. You also should inspect the areas around your pipes and apply caulk to holes and cracks near them on both interior and exterior walls. Consider applying electrical heating tape to pipes, but be sure to carefully follow the instructions to keep your home and family safe. Another option is insulating pipes to prevent them from freezing. Fit exposed pipes with foam rubber or fiberglass sleeves, and add insulation to walls and ceilings as needed to keep your pipes warm. 2. Replace Furnace Air Filters Before Winter Home energy costs become costly, but you can keep costs down by replacing your furnace air filter before winter to help the system run more efficiently. Clogged or damaged air filters force your heating system to run much harder, which can cause it to break down; in fact, replacing air filters is one of the best ways to prolong the life of your home’s HVAC system. Smart homeowners replace furnace air filters in fall because the demand is not high enough for them to drive prices upwards. 3. Check Your Smoke and Carbon Monoxide Detectors As people turn on their heat and keep their windows closed in winter, they put their families at greater risk of house fires and carbon monoxide poisoning. Because heat is necessary during winter, you need to keep your family safe from the potential hazards of heating your home by checking your smoke and carbon monoxide detectors before the first deep freeze sets in. One smart way to keep on top of your detectors is to change the batteries when daylight savings time ends. When you make your clock fall back, install fresh batteries and test your detectors to ensure they are in working order. A few dollars for batteries and a few minutes of testing will give you peace of mind and help your alarms keep your family safe. 4. Repair Concrete If you have noticed that you have sunken or uneven concrete in your driveway, sidewalk, patio, steps, or other areas around your home, you should contact a professional to correct the issue no later than autumn. You also should repair cracks of all sizes before winter approaches. Repairing concrete issues before winter is important because water works its way into the cracks, freezes, expands, and causes more damage to your concrete. You can attempt to repair hairline cracks your concrete sidewalks and driveways yourself this fall. Begin by removing debris from the area by spraying water into it and using a stiff broom or brush. Then, apply a concrete mix to the damaged area or plugging the rack with a premixed filler. If you use a premixed filler in a tube with a caulking gun, overfill the crack and scrape away excess. If you are uncomfortable repairing your concrete yourself, or if the cracks are in your foundation, you should contact a local professional to do the repairs for you before more damage occurs as the weather becomes cold. Being proactive with home maintenance this fall is the best way to avoid costly repairs. You should take steps to prevent frozen pipes, replace furnace air filters before winter, check your smoke and carbon monoxide detectors, and repair concrete around your home. Image via Flickr by Centre for Alternative Technology Article by: Paul Denikin Dadknowsdiy.com [email protected] $100 OffWe want to ring in the New Year with great savings from Concrete Corrections. Do you have settled concrete or erosion problems around your home?

Take $100 Off your next home project estimate! Please mention this ad during your free site visit. Call Today 770-558-5862 This offer expires 1/31/2017 Happy first day of summer y'all! So, by now most homeowners have their money pit, I mean swimming pools, open. It's summer vacation and the neighborhood kids hang out and swim all day. Maybe the neighbors come over in the evenings for a cook out. Do you have that area around the pool where you don't want anyone to see or use? It can be blocked off with planters or outdoor furniture? Put some bright colored tape down, so no one trips. . . Settled pool decking, what happened? How in the world do you fix this, and WHO do I call for this? These are some popular questions from pool owners. To start, the first question tends to fall into two categories: Is there a leak in the pool liner or skimmer? Or was the area not compacted properly during construction? Often times, we see settled or sunken concrete slabs around pools that have simply dropped over time because the soil underneath has finally compacted, which is no longer supporting the weight of pool decking above. If you're lucky, and the company who installed the pool decking layed out the joints correctly, the settled decking piece may not have a new crack across the middle, but is still in good shape. In cases where there was a leak somewhere around the pool, there tend to be larger voided areas and greater degrees of settlement. (We recommend getting that leak fixed first!) Please remember, before beginning any pool deck repair project, the first and most important step is to figure out what caused the damage and then determine the best repair procedure for solving the problem. There are a few ways to fixed settled concrete around the swimming pool. One traditional way of repairing sunken concrete is to simply "tear it out and replace it". This is sometimes more easily said than done. Things get tricky when it comes to the back area of a home. Fancy landscaping, distance to the area of repair, matching decorative finishes and time frame for repair are just a few. Polyurethane foam injection for lifting and supporting swimming pool decks is becoming a more and more popular method of repair. The injection holes tend to be small (approximately 5/8" in diameter), polyurethane foam is incredibly lightweight but very strong, it cures instantly and areas are ready for use immediately, and there is little to no disturbance to landscape around the area. There are so many reasons polyurethane foam is the perfect solution to lift / support settled slabs around the pool! In today's world, it can be overwhelming to have to educate yourself on the problem at hand, then find the correct solution for your settled concrete issues.

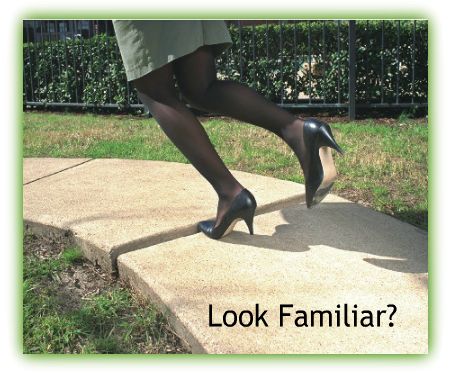

Give us a call today to find out how polyurethane foam injection may be your solution for lifting and supporting settled pool decks. Call 770-558-5862 Consider these top reasons to fixing your sinking and unlevel concrete slabs1. The Problem Always Gets Worse If a slab has cracked or has begun to sink, the issue will not eventually stop or fix itself, it WILL continue to get worse. And when problems get worse, the cost of fixing the issue increases. 2. Resale Value Of Your Home Today's homebuyer doesn't typically want to purchase a home with an unleveled driveway and front walkway, a stoop pulling away from the house, or floors that are cracked and sinking. First impression does make a difference in some cases. Also, be prepared for this to be a "bargaining chip" in the price offer. 3. Appearance Concrete slabs with large voids or settled and uneven do not look safe. 4. Safety Settled or unlevel concrete is unsafe. As a homeowner or landlord, this is incredibly dangerous and open you up to unwanted liability. 5. Water Intrusion

Cracks are exposed to the surrounding environment and when cracks let in water, damage can worsen. 6. Pooling Water Unlevel concrete will encourage low spots where standing water will pool. In cooler months, these pools can freeze, which causes more safety concerns and further damage. 7. Structural Damage Shifting concrete on a ground level can affect the structures above the slab. As a result, doors and windows will start to stick and other structural damages throughout your home may occur. Load bearing walls should be watched closely. If the problem is left too long, cost of repair will increase significantly. For Further Info: Contact Us Today 770-558-5862 [email protected] Spray Foam BreakersLaying down pipelines has always been a back breaking job, but some pipeline companies are utilizing a technology that can ease the process along -- spray foam.

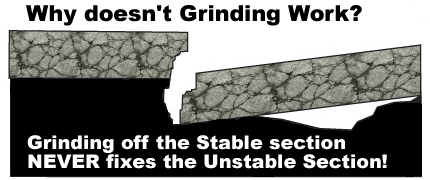

Traditionally sand bags were stacked in the trench around a pipeline at about 50 foot intervals on inclined stretches. Used for erosion control, the sand bags for breakers would slow the flow of water down the trench. And now, life can be made a little easier with the latest in spray foam insulation technology - experts can prepare a trench breaker in minutes - conformed to any shape or condition the application requires - spray foam expands 120 times per second - forming a watertight barrier that won’t break down over time - polyurethane helps hold welded joints together - acts as rock shield - the pipes themselves can also be insulated - It’s also environmentally friendly, containing no CFCs, formaldehyde or ozone depleting agents. This now means pipeline companies are going to be spending less on labor as spray foam is a much more pain free solution to erosion control. Stacking the 30-50 pound sand bags around the pipelines has always been one of the most physically demanding jobs on the site. Laborers would have to stand in the bottom of the trench and position the heavy sandbags around the pipeline by hand. Spray foam is faster! With one or two workers, breakers can be installed in 15-20 minutes, an hour long job for crews with sand bags. Using spray foam can be a cost saver for pipeline companies for that reason. In addition to decreasing expenditures for pipeline companies, spray foam is also a matter of being environmentally responsible. By adhering to the pipe and to the bank, spray foam is very efficient at erosion control and helps to prevent wash outs. Additionally, because of the rigidity of the foam and its adherent qualities, it is very effective at keeping the pipelines in place. Spray foam prevents the pipes form moving and causing an environmental disaster. For more info on spray foam breakers or polyurethane for erosion control, call 770-558-5862 Soil and concrete are constantly moving. When you have poor compaction and erosion involved, things REALLY move. Sidewalk slabs are forever shifting and one of the quick and inexpensive "fixes" is to grind the concrete down to level. One of the problems is that grinding leaves unsightly marks on the finished surface, which some people don't necessarily mind. But for those that have decorative finishes on driveways and pool decking, this is a serious concern that they should know about ahead of time. The real concern here is that the REASON the concrete settled in the first place. Most likely poor compaction or erosion has affected this area, causing slab movement. When grinding the slab, you are essentially shaving off the top side to make level for walking. Nothing is done to stabilize the soil beneath the slab, and so there is a very good chance for resettlement in the future. Especially since water has now found it's way past the walkway or path of least resistance. By injecting structural grade polyurethane material below the slab and lifting the slab back toward original position, you've now pushed down (or compacted) the compromised soil, void filled where soil has been eroded out, and lifted the slab back up. From the top, the sidewalk looks like it did years ago, the colors all match and the slabs are fully supported. Believe it or not, lifting and leveling sunken concrete pricing is very cost effective. We always suggest that homeowners look at all of their options before making a decision. Compare the pros & cons, pricing and estimated time the fix will last.

To find out more about lifting and supporting settled concrete slabs, contact us today 770-558-5862 or email [email protected] A sunken concrete slab whether a sidewalk, driveway, pool deck or patio, will eventually need a concrete repair or replacement. The decision will often come down to the cost, benefits and capability. Concrete Repair

Concrete ReplacementPlanning to replace your sunken concrete, yourself? If so, keep in mind that you'll need to not only pour a new slab, including building a form and finishing the new concrete, you'll need to remove the old concrete. This means breaking it up and hauling it away.

Another point to remember is, WHY did the settlement occur in the first place? When replacing concrete, it is important to make sure the soil base is solid. Otherwise, your newly poured concrete may move and settle again in the near future. Lifting And Supporting Sunken Pool Deck Slabs With Polyurethane FoamIf you're like most in-ground pool owners your concrete pool deck has settled in one or more places causing trip hazards and unsightly conditions. You may have considered having it torn out and replaced but have been holding off due to the expense and inconveniences associated with doing so. With the use of structural grade Polyurethane Foam, we are capable of lifting and leveling settled concrete slabs around pool decks with very minimal disruptions and typically for 1/2 the cost of replacement. Why Has My Concrete Settled?After your pool has been constructed the area around the pool is often back-filled with dirt preparing it for the concrete decking to be poured. In most cases, this soil is improperly compacted and over time as it settles or erodes it no longer supports the weight of the concrete sections,ultimately causing them to settle How Can I Tell If I Have Issues?When the concrete begins to settle you will be able to see signs such as cracks in the slabs, puddling water, trip hazards between sections and/or excessive sloping from and separation at the pool coping. Signs may occur within months or take years to develop but the sooner you identify them, and stabilize the soil, the less damage there will be to the concrete and your pool. We Can HelpWith Concrete Corrections, you have a cost effective alternative and a less disruptive solution to repairing your settled concrete. Often times, pool deck projects can be completed in 1 day and the areas are cured and ready to use immediately. So, you're under a time crunch with selling your home or planning that Labor Day Party, we can work with you on a timely schedule.

We lift and support settled concrete, void fill and stabilize soil all over Atlanta and North Georgia. Call Today 770-558-5862 So, yesterday after seeing our mountain neighbors having some trees cut, for better views off their back deck, we were inspired to discuss: The Effects Of Cutting Trees & Erosion. How trees stabilize soil and prevent erosion, particularly on slopes. How your concrete walkways, pool decks and driveways, EVERYTHING around your house, is effected by erosion and cutting all the trees away from your house, indeed has an impact. Even just ONE tree. We thought, well maybe they could've just cut some of the branches off or topped the tree (to make it shorter) and see over it, in an effort not to kill it completely. And did they plant any trees anywhere else, to replace the ones that were cut? Obviously there are "problem trees" out there that need to be addressed (disease, locations, etc), and in an effort to not get too personally involved we will stop there, but we found some interesting reading out there. So take a look and maybe take 1 or 2 things away from this today.

Read Here about the Value Of Living Trees - at the living tree educational foundation |

Archives

November 2017

Categories

All

|

|

Copyright © 2024 l Concrete Corrections by ISS, Inc

|

Who We Are

We are a family owned and operated company based in coastal South Carolina and dedicated to providing a cost effective repair to compromised or settled concrete slabs and soil areas around the home or business, with access to a vast array of knowledge and polyurethane products. We promise to produce long lasting results that we are all proud of.

|

Contact Us

|

RSS Feed

RSS Feed