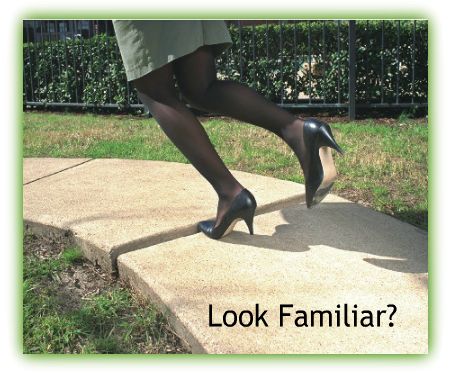

Consider these top reasons to fixing your sinking and unlevel concrete slabs1. The Problem Always Gets Worse If a slab has cracked or has begun to sink, the issue will not eventually stop or fix itself, it WILL continue to get worse. And when problems get worse, the cost of fixing the issue increases. 2. Resale Value Of Your Home Today's homebuyer doesn't typically want to purchase a home with an unleveled driveway and front walkway, a stoop pulling away from the house, or floors that are cracked and sinking. First impression does make a difference in some cases. Also, be prepared for this to be a "bargaining chip" in the price offer. 3. Appearance Concrete slabs with large voids or settled and uneven do not look safe. 4. Safety Settled or unlevel concrete is unsafe. As a homeowner or landlord, this is incredibly dangerous and open you up to unwanted liability. 5. Water Intrusion

Cracks are exposed to the surrounding environment and when cracks let in water, damage can worsen. 6. Pooling Water Unlevel concrete will encourage low spots where standing water will pool. In cooler months, these pools can freeze, which causes more safety concerns and further damage. 7. Structural Damage Shifting concrete on a ground level can affect the structures above the slab. As a result, doors and windows will start to stick and other structural damages throughout your home may occur. Load bearing walls should be watched closely. If the problem is left too long, cost of repair will increase significantly. For Further Info: Contact Us Today 770-558-5862 [email protected]

15 Comments

Spray Foam BreakersLaying down pipelines has always been a back breaking job, but some pipeline companies are utilizing a technology that can ease the process along -- spray foam.

Traditionally sand bags were stacked in the trench around a pipeline at about 50 foot intervals on inclined stretches. Used for erosion control, the sand bags for breakers would slow the flow of water down the trench. And now, life can be made a little easier with the latest in spray foam insulation technology - experts can prepare a trench breaker in minutes - conformed to any shape or condition the application requires - spray foam expands 120 times per second - forming a watertight barrier that won’t break down over time - polyurethane helps hold welded joints together - acts as rock shield - the pipes themselves can also be insulated - It’s also environmentally friendly, containing no CFCs, formaldehyde or ozone depleting agents. This now means pipeline companies are going to be spending less on labor as spray foam is a much more pain free solution to erosion control. Stacking the 30-50 pound sand bags around the pipelines has always been one of the most physically demanding jobs on the site. Laborers would have to stand in the bottom of the trench and position the heavy sandbags around the pipeline by hand. Spray foam is faster! With one or two workers, breakers can be installed in 15-20 minutes, an hour long job for crews with sand bags. Using spray foam can be a cost saver for pipeline companies for that reason. In addition to decreasing expenditures for pipeline companies, spray foam is also a matter of being environmentally responsible. By adhering to the pipe and to the bank, spray foam is very efficient at erosion control and helps to prevent wash outs. Additionally, because of the rigidity of the foam and its adherent qualities, it is very effective at keeping the pipelines in place. Spray foam prevents the pipes form moving and causing an environmental disaster. For more info on spray foam breakers or polyurethane for erosion control, call 770-558-5862 |

Archives

November 2017

Categories

All

|

|

Copyright © 2024 l Concrete Corrections by ISS, Inc

|

Who We Are

We are a family owned and operated company based in coastal South Carolina and dedicated to providing a cost effective repair to compromised or settled concrete slabs and soil areas around the home or business, with access to a vast array of knowledge and polyurethane products. We promise to produce long lasting results that we are all proud of.

|

Contact Us

|

RSS Feed

RSS Feed